Introduction

Routine operation and maintenance works play the most essential part at keeping an optimized production flow and yield of an industrial plant. Correctly scheduled maintenance work ensures production system working at its expected efficient at all time as well as minimizing potential upsets. It is not uncommon for a plant operator to prepare and print out all the reference documents, which usually consist of Checklist, Operation & Maintenance Manual (OMM), P&ID, Layout or Plot Plan, Equipment Data Sheets and Equipment OMM as minimum prior to any operation or maintenance task. After that, could you imagine walking around with stacks of papers/files or flipping through hundreds of pages just to retrieve one simple information? Apart from these time consuming tasks, another common issue is that operators spends too much hours on identifying and locating equipment especially at elevated/out-of-reach areas and areas with complex piping system in the plant. The level of difficulty increases along with the complexity of the plant system, which is most of the time unavoidable due to space or cost constraint. That said, if aforementioned issues can be resolve, plant owner could possibly shorten the operation or maintenance schedule that eventually leads to a shorter plant downtime and less man hours spent, essentially saving cost in operating expenditure (OPEX).

Description

Augmented Reality (AR) comes into play by adding values on top of the 3D models generated during engineering and construction phase of a new system through a simple and customizable mobile app. By definition, AR is a technology that superimposes a computer generated image on a user’s view of the real world, thus providing a composite view. In fact, this is not something new in the industrial world but speaking in terms of utilizing this technology in plant operation seems understated at the moment. Through smart devices, for instance smart phones, or even a more sophisticated one like the Microsoft HoloLens, the user can superimpose the life-size digital model of a plant system onto the as-built/constructed system at site. By doing so, it serves as a real-life directory at hand. With the help of the information imposed on digital 3D model that is scaled to a presentable view, operators can move around the plant at ease just like a self-guided tour. Locating an equipment couldn’t have been easier than simply keying in the equipment tag number and pressing the search button. Connecting the smart device to cloud service and extracting real-time data from control system are some examples worth looking into in future development.

AR mobile app can also be utilized as a training tool by the operator to get familiarized with plant environment, and ultimately manage to swiftly identify location of equipment locations at plant. Similarly, material handling preparation work will be so much faster as the operator no longer has to go through all the hassle on finding the equipment locations through papers or documents.

Speaking in case of an offshore maintenance work, whereby a real-life walk-through prior material handling preparation is not feasible or less practical, it can be coupled with Synergy’s 3D operator training simulation (OTS) tool [1] to visualize the offshore environment in VR mode in any onshore safe environment and prepare the necessary maintenance tools. During mobilization to offshore platforms, we can again make use of the AR mobile app to the same extend as mentioned above. Offshore maintenance work can thus be executed in a safe and hassle free environment.

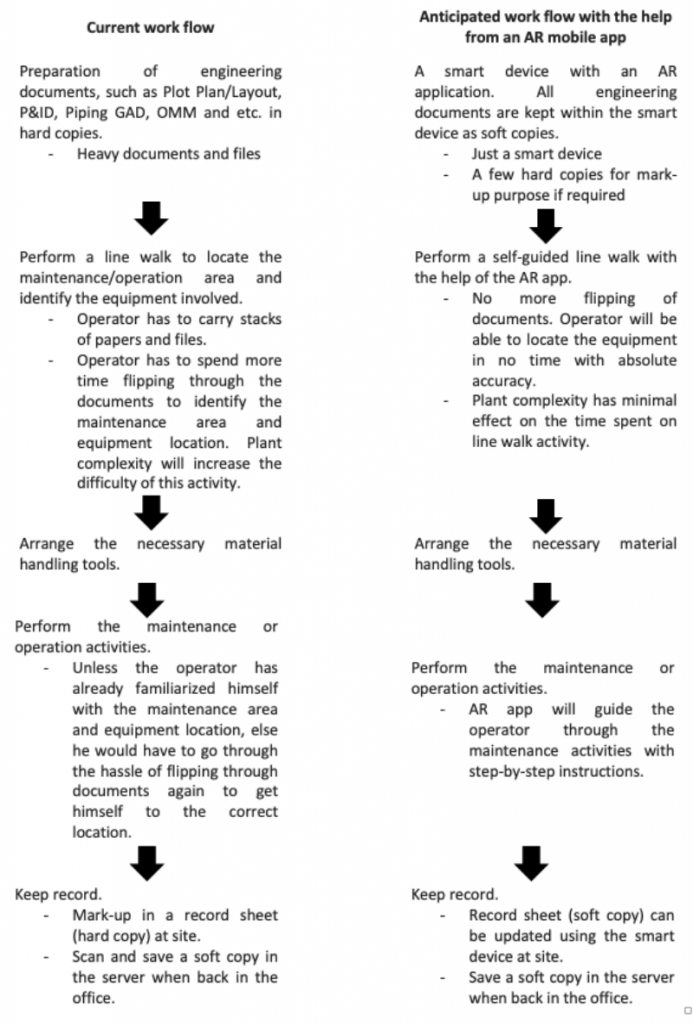

To summarise, let’s look at the following common scenario that demonstrates how work can be simplified with an AR mobile app:

Introducing Synergy Immersive and Technology Environment (SITE) App supported with Augmented Reality (AR) Technology

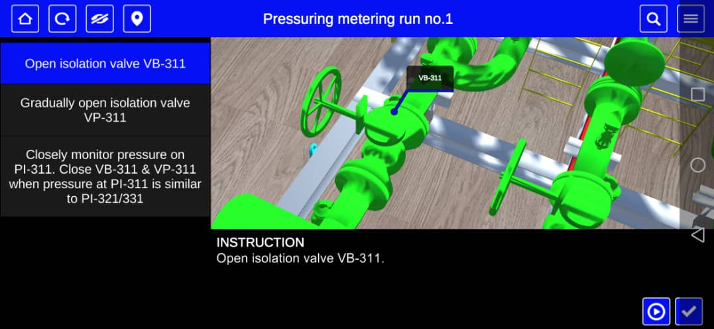

The first prototype of Synergy Immersive and Technology Environment mobile app, in short SITE app was developed based on a gas metering station in Johor, Malaysia, a wholly owned by Petronas Gas Berhad. It was customized to suit the operational and maintenance requirement of this gas metering station. In this demo version of SITE app, a self-guided flowmeter proving operation mode was developed through a series of instructions that had been programmed in the AR mobile app. Three major functions of SITE app comprise of System Operation Mode, Equipment Data and Maintenance Record. System Operation Mode contains step-to-step instructions of several operational modes; Equipment Data contains all engineering documents; Maintenance Record keep records of all activities. Following shows a sneak peek from SITE app.

Figure 1: Home screen of SITE app consisting of three major modes/functions

Figure 2: User performing meter proving operation through the help from SITE app

Figure 3: SITE app guiding the user to the relevant equipment through a red arrow

Figure 4: Upon completion of work, user may capture the record immediately in SITE app

Key Feature

- Add value onto the 3D model generated as part of the deliverables during engineering and construction phase.

- Enable self-guided walk through of a real-life plant for training purpose or preparation of material handling equipment for specific maintenance task.

- Guide user to specific equipment without going through the hassle of searching the equipment’s location within piles of engineering drawings.

- Enable the storage of engineering documents’ soft copy in the smart device.

- Enable maintenance record keeping in the smart device.

- Shorten maintenance schedule which in turn reduces production downtime and operators’ man hours.

- Reduce operational error through guides and instructions preset within the AR tool suited for plant operation and maintenance work.

- Customizable to suit any operational or maintenance requirement.

Reference

[1] Synergy’s Insight: Operation Training Simulator http://www.synergyengineering.com/insights/operating-training-simulations-in-a-virtual-3d-environment/