Power plants commonly utilize conventional fuel sources from natural gas (from production wells), coal or biofuel products to produce electricity. Who would have thought that a fuel source could also be found from a deepwater lake in Africa?

This spectacular phenomenon is found at Lake Kivu, Rwanda. The lake encompasses a surface area of 2700 km2 at an altitude of 1462 m, with 485 m in depth. Lake Kivu is situated on the border between the Democratic Republic of the Congo and Rwanda, and it is located in an area with one of the highest population densities and population growth rates in the AGL region. The lake basin has a population of about 2 million people!

The discovery of methane in the deep waters of the lake was first made in 1935, while trying to understand why there were no fish in the lake. Later, it was discovered that the anaerobic decomposition of the organic matter present in the lake contributes to its methane production, which is high soluble in the deepwater lake at low ambient temperatures. This traps the highly concentrated methane deep within the lake.

Through the various studies that was done by the scientific community, it was predicted that there is a significant risk of a sudden release of large quantities of these gases within the next 100-200 years without the production of methane and carbon dioxide. Such a release has the potential to kill many thousands of people living around the lake from asphyxiation. Rather than just venting the ± 2 trillion cubic feet (56.6 km3) of methane, this project would use the extracted methane for power generation, for the commercial benefit of the people of Rwanda and also reducing the risk of an environmental disaster. Through 7 reciprocating gas engine generator sets, the entire project is expected to have a maximum net output of 56MW.

With this deeply embedded fuel source, the main challenge was to think of an innovative process solution to allow for the extraction of the methane from the deepwater lake in a safe manner.

A huge concern surrounding this was that the destabilization of the lake parameters due to the extraction might occur, potentially causing catastrophic damage to the entire population within the vicinity of Lake Kivu due to asphyxiation / outburst of flammable gas to the lake’s surface. Hence, it was crucial to ensure that the extraction process is performed and designed for safe operation over a prolonged period.

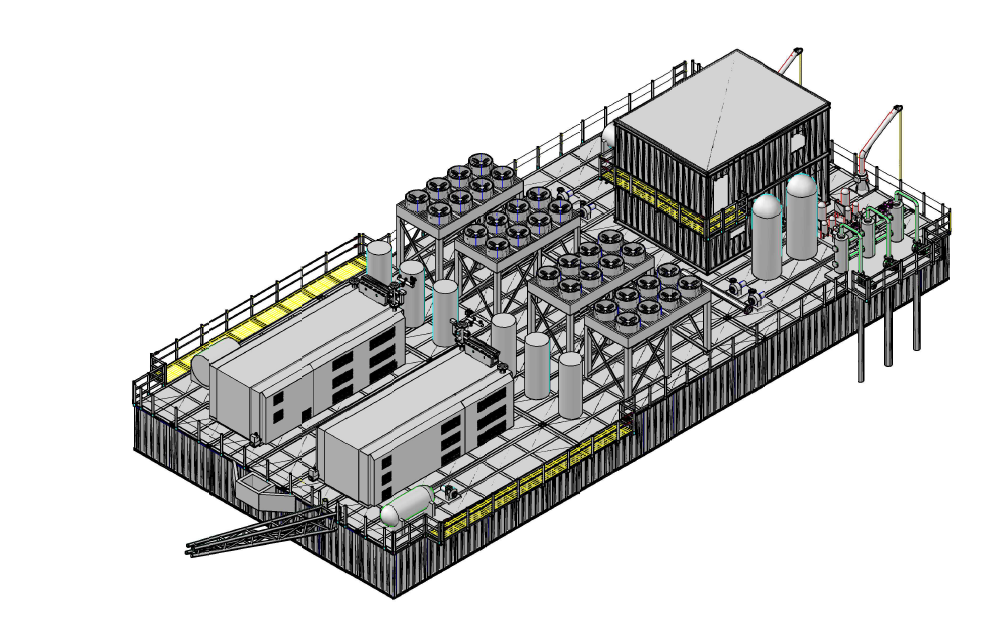

Figure 1: Lake Kivu Methane Extraction Facility

Synergy’s methane extraction process was designed to be self-sufficient- powering the methane extraction process and supply additional concentrated methane sufficient to generate 14 MW of power at the power plant. The methane extraction process design includes an auto-siphon separator, compression trains, a purification system, export pipelines and associated utility systems required to facilitate the process. Safety shutdown systems and overpressure protection systems were also designed to ensure safe operation during the extraction process. To prevent the risk of gas eruptions, several models were used to predict the acceptable depths to extract and release the deep water.